In the world of apparel production, efficient garment sourcing is the key to maintaining quality, minimizing cost, and ensuring on-time delivery. Whether you’re a new fashion brand or an established retailer, understanding the full sourcing process—from sampling to shipment—can help you build a more reliable supply chain and avoid costly mistakes.

Here’s a step-by-step breakdown of the complete garment sourcing process followed by professional buying houses and manufacturers.

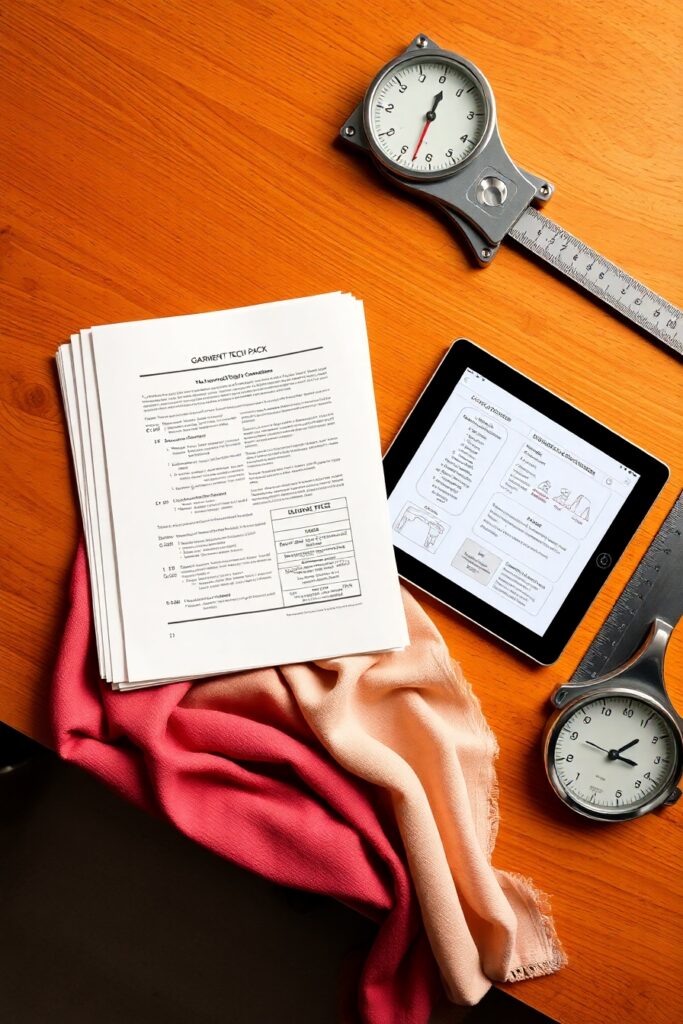

1. Tech Pack & Product Development

The journey begins with the tech pack, which includes all design specifications—fabric type, measurements, stitching details, trims, and accessories. Buyers share this with the buying house or supplier, who interprets it and starts sourcing raw materials and trims accordingly.

👉 Goal: Align buyer expectations with manufacturer capabilities before sample development.

2. Sampling Process

a. Proto Sample:

Initial sample based on the tech pack to verify construction and design.

b. Fit Sample:

Used to check size specs and fitting.

c. Pre-Production (PP) Sample:

Final sample made with actual fabric and trims for bulk approval.

Sampling helps in confirming all details and avoiding confusion during bulk production.

3. Costing & Price Negotiation

Once the sample is approved, the supplier provides a detailed quotation. This includes:

- Fabric & trim costs

- Labor & overheads

- Packaging

- Shipping (FOB or CIF)

Buyers and suppliers negotiate to reach a mutually beneficial price.

4. Order Confirmation & Contract

After pricing is finalized, both parties sign a Purchase Order (PO) or formal contract that outlines:

- Quantity

- Style details

- Delivery timeline

- Payment terms

This formal agreement sets the ground for production.

5. Raw Material Sourcing

The supplier or buying house begins sourcing fabrics, trims, threads, labels, and packaging materials. For sustainable buyers, certified eco-friendly materials are selected (like GOTS, OEKO-TEX fabrics).

6. Production Planning

Factories plan the production line based on order volume and timeline. This includes scheduling fabric cutting, stitching, and finishing. The buying house oversees all planning and factory coordination.

7. Quality Control & Inspections

Strict quality checks are conducted during and after production:

- Inline inspection

- Midline inspection

- Final random inspection (FRI)

Quality control ensures the product meets the buyer’s standards and avoids costly reworks or returns.

8. Packing & Documentation

Approved goods are packed as per buyer instructions—usually with poly bags, hang tags, and barcodes. Export documentation is also prepared:

- Invoice

- Packing list

- Bill of Lading (B/L)

- Certificate of Origin

9. Shipment & Delivery

The final step is shipping the goods. Depending on the buyer’s requirement, shipment can be by sea, air, or courier. The buying house tracks the logistics and shares updates with the buyer until delivery.

✅ Why It Matters

Each stage of the garment sourcing process plays a critical role in delivering high-quality products on time. A professional buying house ensures all steps are handled efficiently—with clear communication, quality control, and accountability.

Conclusion

From the first sketch to the final shipment, garment sourcing is a detailed and collaborative process. Brands looking to scale production while maintaining quality and cost-efficiency should work with experienced sourcing partners who understand the entire supply chain. With the right approach, sourcing from countries like Bangladesh can be your greatest competitive advantage.

🔍 Need help with your garment sourcing?

At TSR Creative Limited, we handle everything from sampling to shipment with quality, compliance, and transparency. Contact us today to start your sourcing journey the right way.

Md

Amazing

badol

Thanks